The Pride Tool Difference

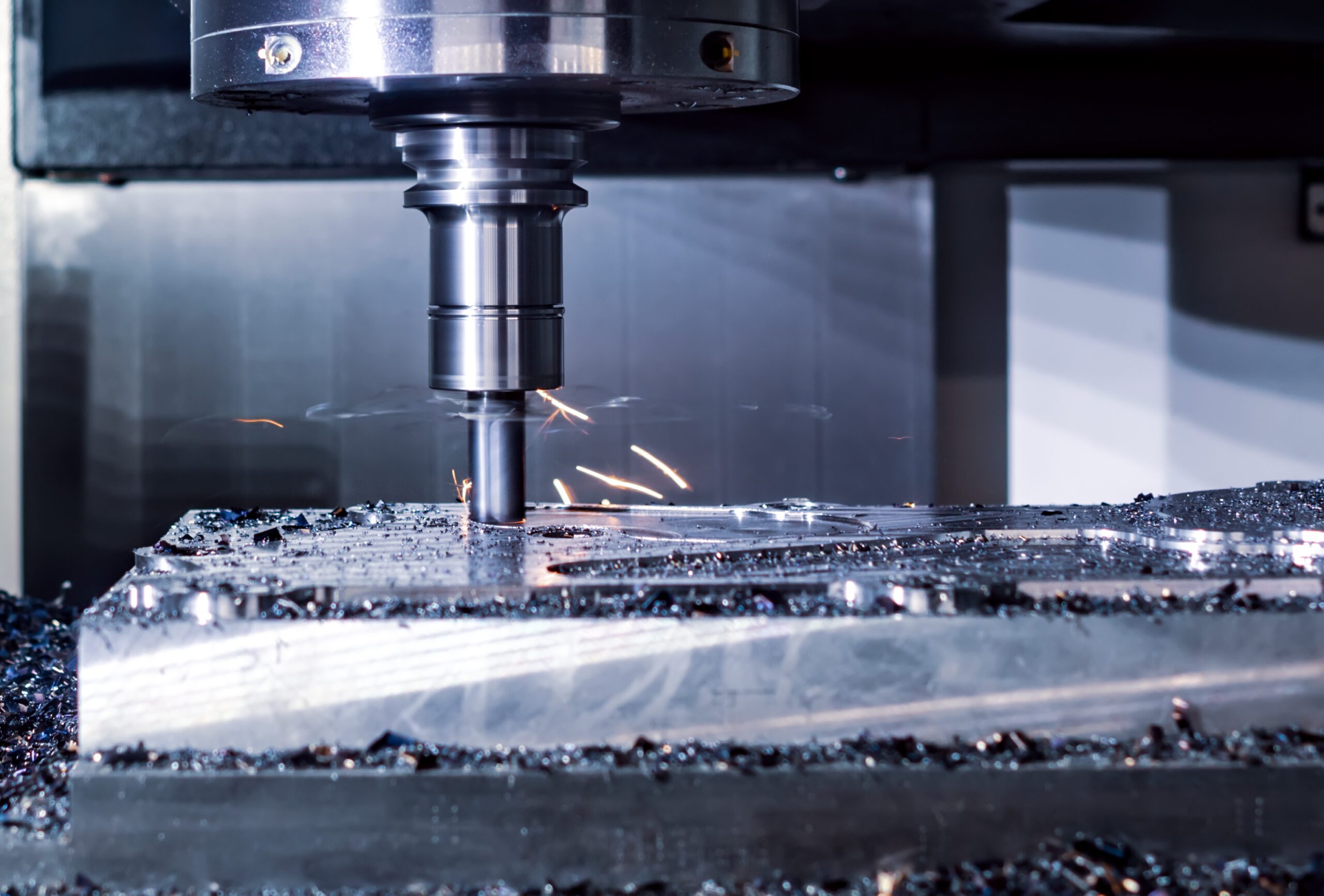

Precision CNC Milling

EXPERIENCE, QUALITY, DEDICATION

A leader in manufacturing for over 20 years, Pride Tool offers precision CNC Milling services for multiple industries and wide-reaching applications.

Our CNC Milling

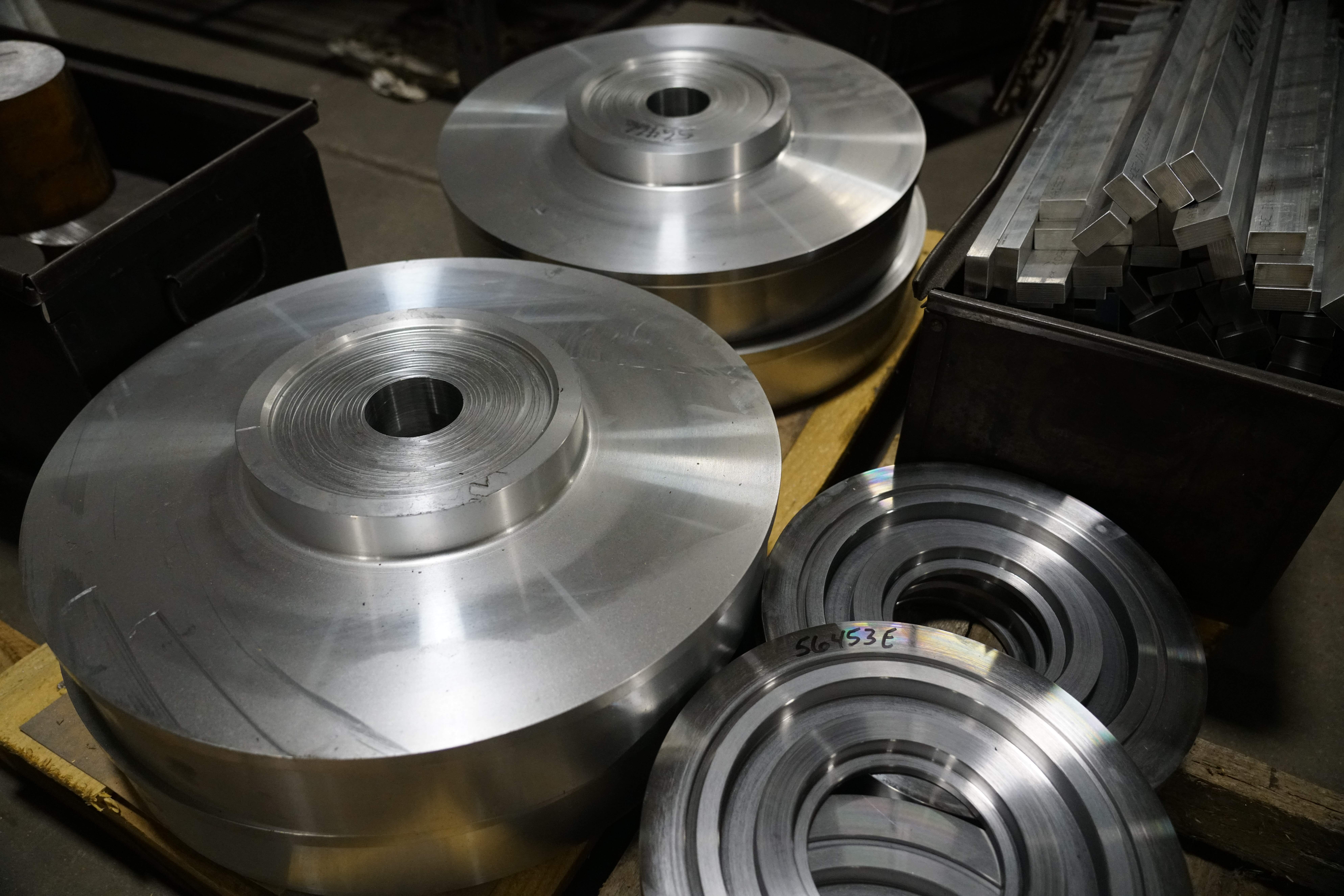

Pride Tool can expertly carry out a full set of machining processes with accuracy and consistency including milling, drilling, thread forming, countersinking, pocketing, facing, and reaming among others. We work with a range of materials including stainless steels, carbon steels, aluminum, brass, bronze, copper, exotics, super alloys, plastics, and all grades of tubing and piping. We employ state-of-the-art CAD/CAM modeling and MasterCam software and have inside programming capabilities.

Our state-of-the-art vertical machining centers feature 3- and 4-axis machines equipped with CNC controlling options, and three or four-jaw chuck fixturing. We are able to machine complex component parts up to 60" long x 27.6" wide x 25" high while holding tolerances as close as ±.0001". Rapid turnaround times and competitive pricing for short to long-run production volume are our specialties.

- Rapid turnaround times

- Competitive pricing

- Long and short-run production volume

Technical Data

We take quality control very seriously, employing CMM for digital inspection, and on-site inspectors to perform first-article testing. Our efficiency efforts include practicing lights out as well as lean manufacturing. Our processes and products conform to stringent standards such as various Mil-spec and ASTM requirements.

- 3 & 4 axis CNC controlled vertical machining centers

- Three or four-jaw chuck fixturing

- Sizes up to 60" long x 27.6" wide x 25" are standard

- Tolerances held as close as ±.0001".

Other services we offer include reverse engineering, assembly, pressing, welding, and painting to name a few.

For more information about our precision CNC milling services and other manufacturing options contact us.

Request A QuoteRequest A Quote

Learn More

Got a question?